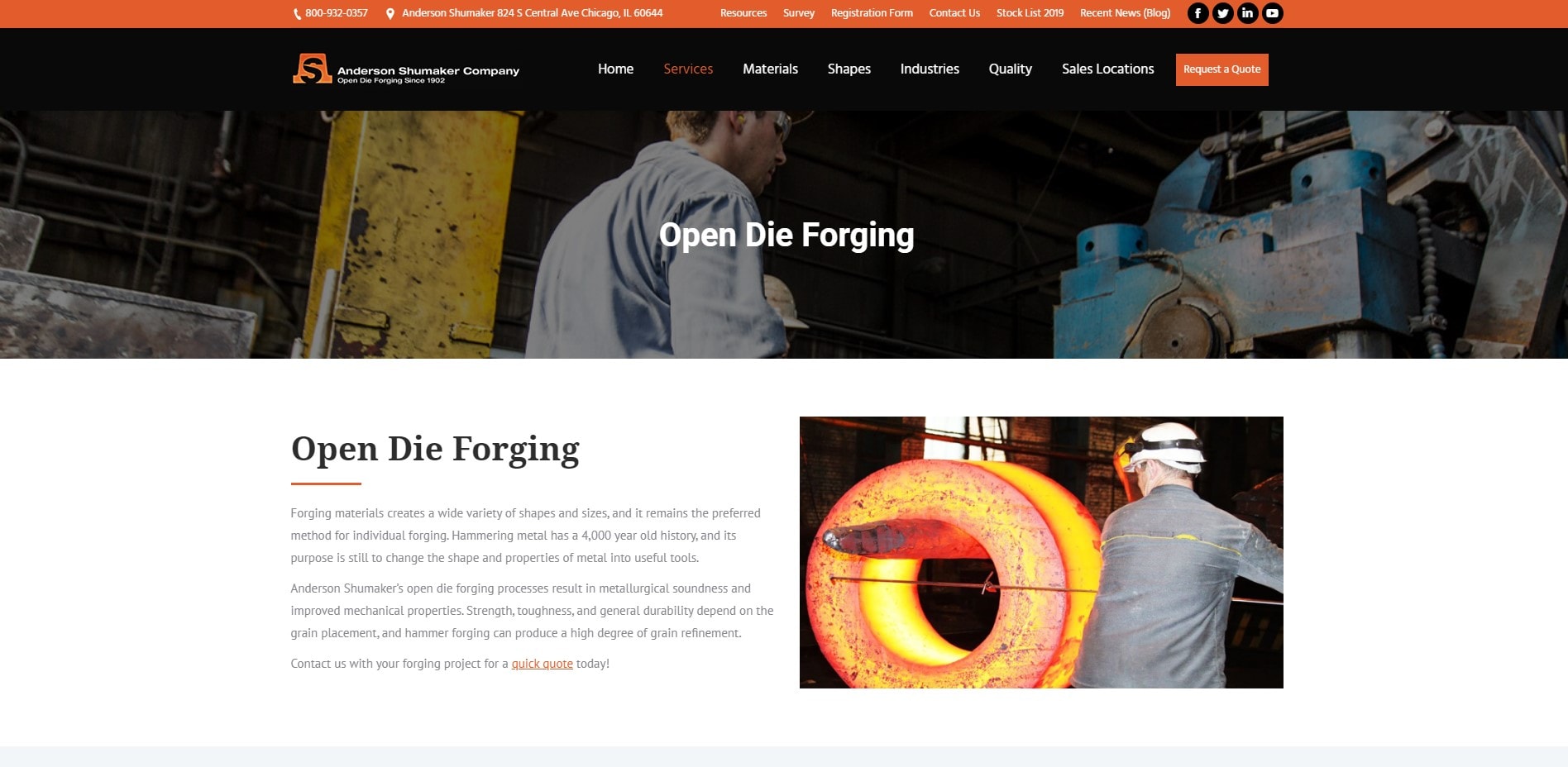

Open die forging is the process of bending metal pieces or workpieces into a desired shape using open dies. The material is formed during this forging process by positioning the workpiece on a stationary anvil and using a power hammer to strike it. Open-die forging is not the final process; secondary machining procedures help shape the material further. Read More…

Although we have over 100 years of experience, we are committed to continually expanding our offerings in all industries. We are not content to remain as we are, but we continually work to improve our products and processes each and every day.

DEECO Metals has been a leading supplier and manufacturer of quality forgings, aluminum forgings, alloy steel forgings and steel forgings since 1986. Our forging presses range from 45 tons to 1600 tons. Expect exceptional service and high-quality forgings at reasonable prices.

From the first forging to the last, Walker Forge will match your exacting standards for superior consistency in die forging. Our satisfied customers will tell you that they receive the most reliable carbon alloy and stainless steel forgings – part-to-part and lot-to-lot – in medium to high-volume applications. Want to increase your products’ performance and boost productivity, choose Walker ...

At W.E. Hoban, we take pride in being a trusted name in the forging industry, delivering strength, reliability, and precision in every product we manufacture. Our expertise lies in producing high-quality forgings that meet the demanding requirements of industries ranging from heavy machinery and transportation to energy and defense.

More Open Die Forging Companies

Open Die Forging: Comprehensive Guide, Applications & How to Choose the Best Supplier

Open-die forging is a versatile metal forging process highly valued in industrial manufacturing, art smithing, and custom metalwork. This forging method is ideal for short production runs, prototyping, and producing parts with superior mechanical properties. In addition to shaping metal, open-die forging improves material integrity by reducing porosity, aligning the grain structure, and enhancing overall strength. As a result, forged metal components created with open-die techniques exhibit exceptional durability and wear resistance, making them a top choice for critical applications in industries such as aerospace, oil and gas, power generation, transportation, and heavy equipment manufacturing.

What Is Open Die Forging?

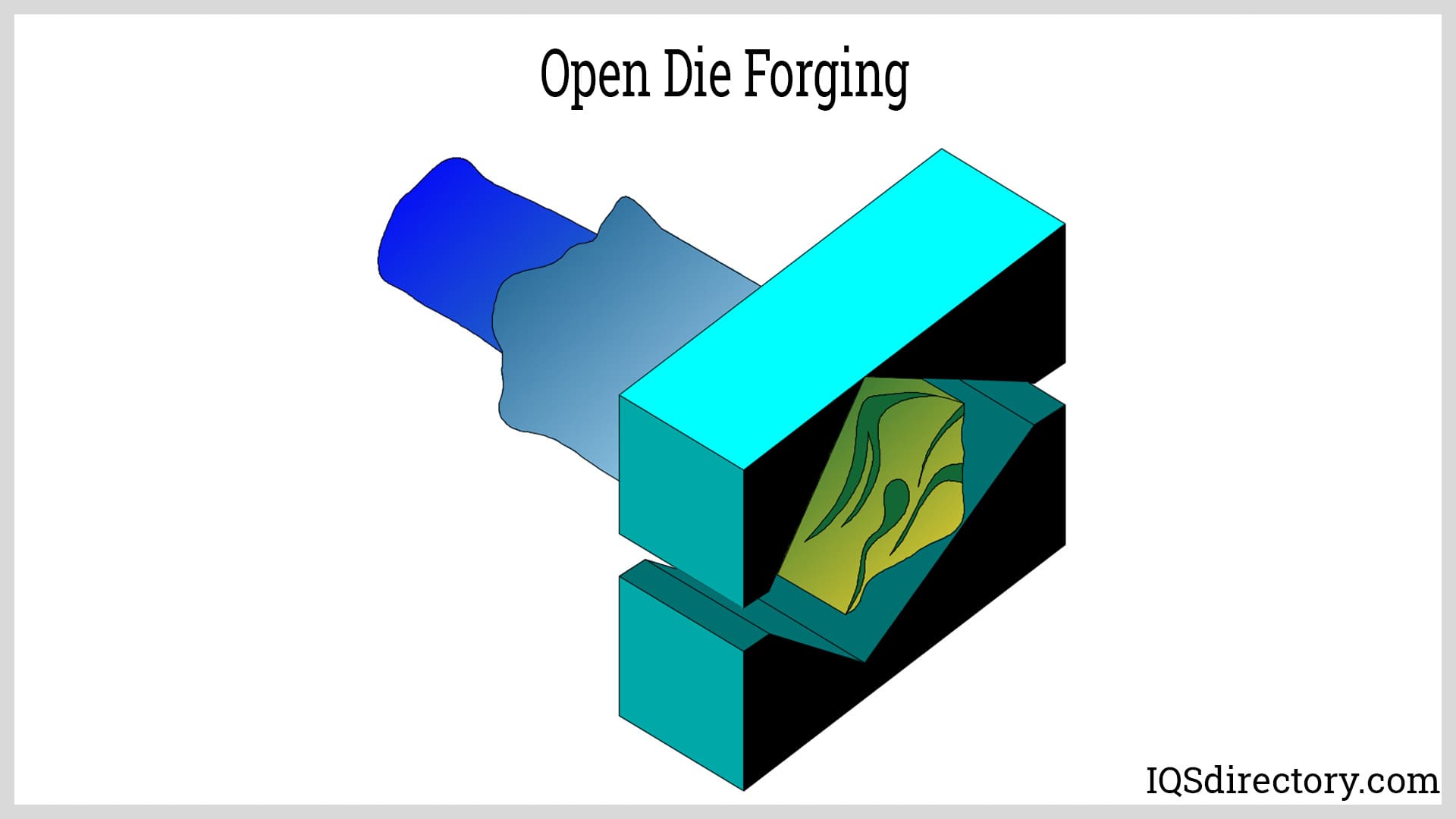

Open-die forging, also known as free forging or smith forging, is a metalworking process where the workpiece is shaped between flat or contoured dies that do not completely enclose the material. This process is distinct from closed-die forging (impression die forging), where dies form a complete cavity around the part. In open-die forging, the operator or automated system manipulates the hot metal, allowing it to be forged into a wide range of sizes and shapes. This flexibility makes open-die forging especially suitable for large, custom, or low-volume forged parts, as well as for producing preforms for further processing.

Open Die Forging: How the Process Works

Open-die forging typically involves heating a metal billet, ingot, or bloom to a specified forging temperature (usually between 1200°C and 1300°C for steel) to achieve optimal plasticity. The heated workpiece is then placed on a stationary anvil, and a series of controlled blows or presses are delivered using a hammer or hydraulic press equipped with a flat, convex, or concave die. The smith or operator frequently repositions and rotates the workpiece, allowing for incremental deformation and precise control over its final dimensions and properties.

Why Choose Open Die Forging Over Other Methods?

Open-die forging stands out for its ability to produce large, simple, or custom-shaped metal parts with superior mechanical properties and grain flow. Unlike casting or machining from billet, open-die forging consolidates internal defects and aligns the grain structure, resulting in parts with higher strength, impact resistance, and structural integrity. Buyers often compare open-die forging to closed-die forging or rolled ring forging when deciding which process best suits their project requirements. If you’re unsure which forging method is right for your application, consider asking:

- What are the size and shape requirements of my part?

- Do I need superior fatigue resistance or impact toughness?

- Is custom, low-volume production preferred, or do I require high repeatability for large runs?

- How critical is directional grain flow or reduced porosity in my component?

Primary Components and Equipment Used in Open Die Forging

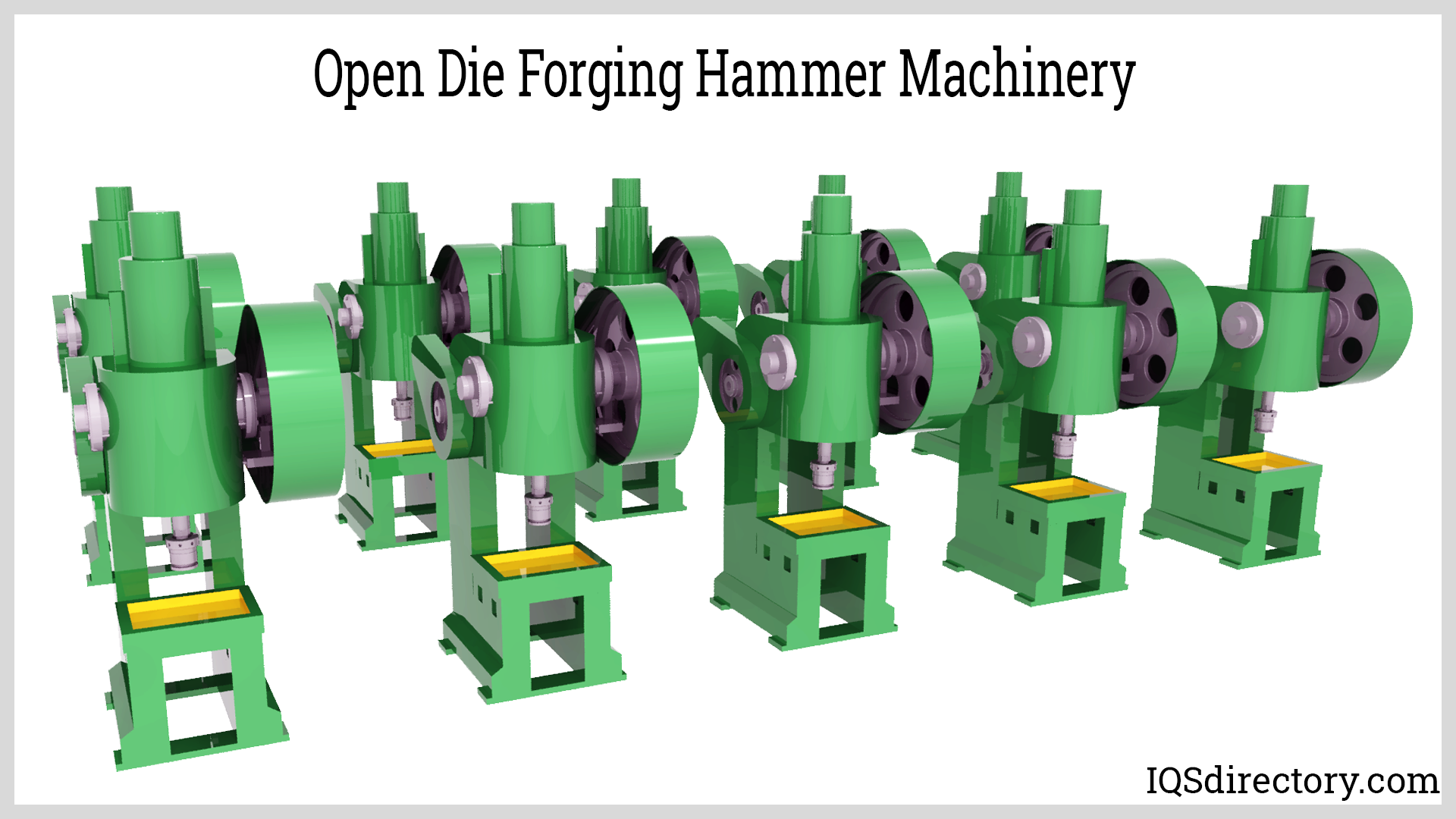

Manufacturers utilize specialized forging machinery to achieve the precise force and temperature control required for open-die forging. The main components of an open-die forging setup include:

- Forging Hammer or Hydraulic Press: Delivers the repeated blows or pressure needed to deform the metal workpiece.

- Forging Dies: Usually flat but may be contoured (concave or convex) to facilitate specific shapes or surface features. Dies can also be customized for punching holes or trimming excess material.

- Stationary Anvil: Supports the workpiece during forging operations and absorbs impact forces.

- Manipulators: Robotic arms or manual tools used to rotate, reposition, and handle the heated metal during forging. This ensures uniform deformation and grain alignment.

- Heating Furnaces: Heat the metal to the appropriate temperature range for forging, ensuring ideal plasticity and minimizing the risk of cracking or other defects.

Key Steps in the Open Die Forging Process

The open-die forging process can be broken down into several essential steps:

- Heating: The metal billet or ingot is heated in a furnace to the desired forging temperature.

- Positioning: The workpiece is placed on the anvil, and dies are aligned for the initial hammering or pressing action.

- Forging: The operator or automated system applies a series of blows or presses, incrementally shaping the metal. The workpiece is frequently rotated and repositioned for uniform deformation.

- Inspection: The forged part is visually and dimensionally inspected to ensure it meets required specifications.

- Cooling: The finished part is cooled in a controlled environment to optimize grain structure and mechanical properties.

Open Die Forging Procedures and Techniques

Open-die forging encompasses a range of techniques, each optimized for different shapes, sizes, and application requirements. The main operations include:

Cogging (Ingot Breakdown)

Cogging is a primary open-die forging operation where a large ingot is repeatedly compressed and elongated using flat, V-shaped, convex, or concave dies. This process reduces the ingot’s cross-section, eliminates internal voids, and refines the grain structure. By manipulating the metal in this way, manufacturers can consolidate flaws such as holes and porosity, resulting in a stronger, more homogeneous material ideal for subsequent forging or machining processes.

Drawing (Solid Forging)

Drawing, sometimes called solid forging, involves lengthening a heated billet, bloom, or ingot to achieve a part with a much greater length than its cross-sectional area. This process is commonly used to manufacture long shafts, rods, and bars, and is essential for applications where directional grain flow and strength are critical.

Upsetting

Upsetting is the process of increasing the cross-sectional area of a metal part while reducing its length. The workpiece, positioned vertically beneath the forge hammer or press, is subject to force that shortens its axial dimension. Flat dies are typically used in this operation, making it ideal for producing components such as flanges, hubs, or thick discs that require substantial cross-sectional mass for strength or assembly purposes.

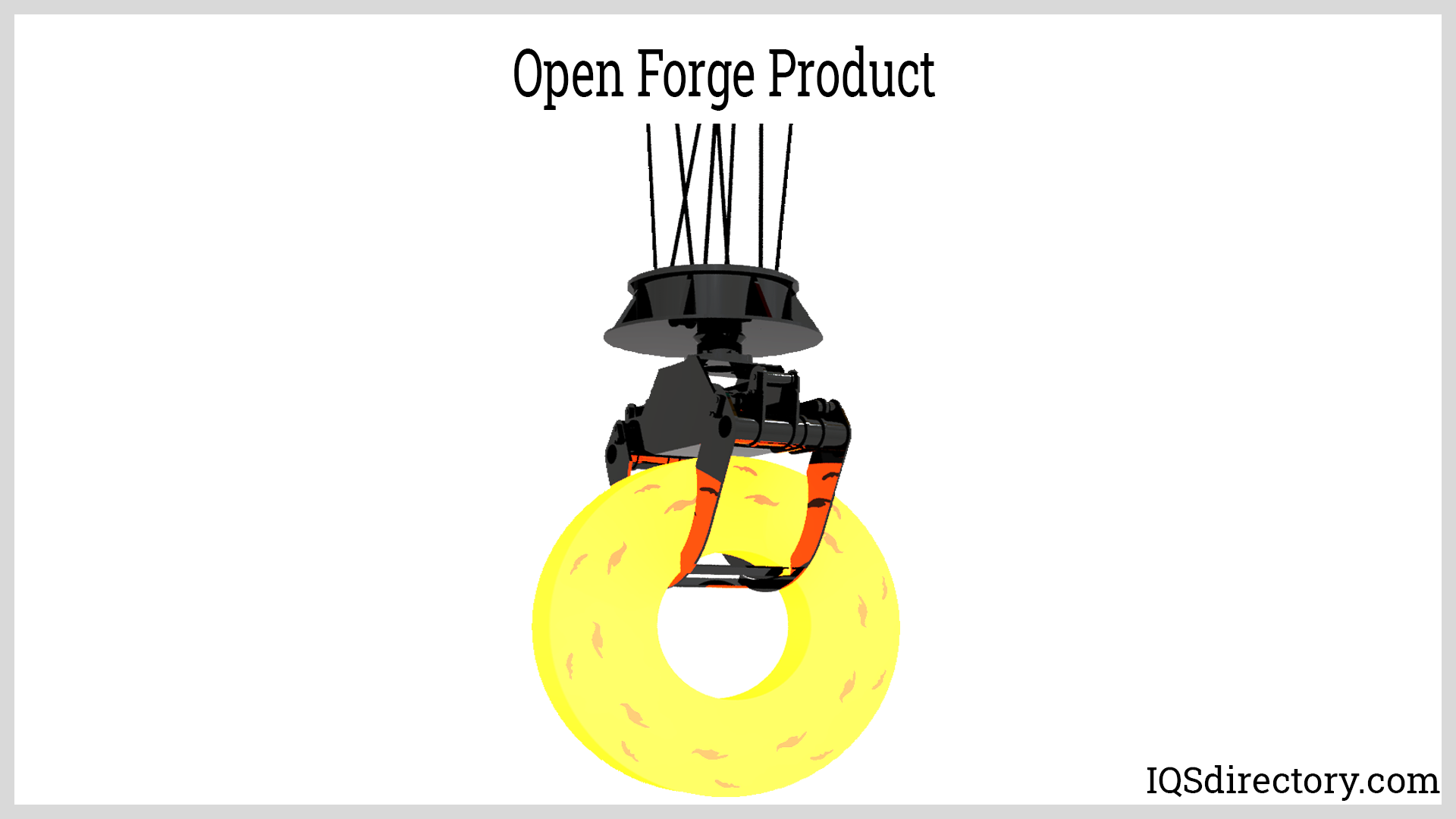

What Types of Parts Can Be Made with Open Die Forging?

One of the greatest strengths of open-die forging is its flexibility in producing a wide range of part geometries and sizes. Common products forged using this process include:

- Shafts (step shafts, spindles, or shafts with integrated flanges)

- Discs and rings

- Blocks and cylinders

- Sleeves, flats, rounds, and hexagons

- Custom-shaped preforms for further forging or machining

- Critical components for the aerospace, defense, energy, mining, and transportation industries

Benefits of Open Die Forging

The open-die forging process offers a unique set of advantages that make it the preferred choice for many high-performance and safety-critical applications:

- Superior Mechanical Properties: Open-die forging aligns the internal grain flow along the part’s primary axis, producing components with increased tensile strength, impact resistance, and fatigue life.

- Reduced Porosity and Defects: The forging process eliminates voids, gas pockets, and other internal flaws, resulting in higher structural integrity compared to cast or machined parts.

- Enhanced Wear and Corrosion Resistance: Forged parts are more durable and resistant to harsh environments due to their refined microstructure.

- Greater Design Flexibility: Open-die forging accommodates large, custom, or one-off components, with fewer tooling costs compared to closed-die forging or casting.

- Material Efficiency: The process minimizes material waste by allowing near-net-shape forging, especially for oversized or unconventional geometries.

- Large Part Capability: Open-die forging can produce individual parts weighing up to 150 tons, making it ideal for heavy industry and infrastructure projects.

- Improved Machinability: Grain refinement and uniformity make forged metals easier to machine to tight tolerances.

Open Die Forging Materials: What Metals Are Used?

Open-die forging can be performed on a variety of ferrous and non-ferrous metals to meet the needs of diverse industries:

- Carbon Steel and Alloy Steel (including stainless steel and tool steels): Common for shafts, gears, and heavy machinery components

- Aluminum, copper, brass, and bronze: Used for lightweight components and specialized electrical or marine applications

- Nickel-based Alloys (such as Inconel, Monel, and Hastelloy): Essential for high-temperature or corrosive service in aerospace, chemical processing, and power generation

- Titanium: Preferred for aerospace, medical, and high-performance automotive applications where strength-to-weight ratio is critical

- Superalloys and exotic metals for demanding environments

When specifying materials for open-die forging, consider factors such as:

- Required mechanical properties (strength, toughness, ductility)

- Operating environment (temperature, corrosion, wear)

- Post-forging machining or heat treatment needs

- Application-specific standards or certifications (such as ASTM, ASME, or ISO requirements)

Industries and Applications Using Open Die Forging

Open-die forging is integral to sectors requiring high-reliability, high-performance parts that must endure extreme loads, temperatures, or corrosive conditions. Key industries and typical applications include:

- Aerospace: Landing gear, engine compressor discs, turbine shafts, and structural members

- Oil & Gas: Drill collars, valve bodies, connector flanges, and pipeline components

- Power Generation: Turbine rotors, generator shafts, and nuclear reactor parts

- Shipbuilding & Marine: Propeller shafts, rudder stocks, and anchor shanks

- Mining & Heavy Equipment: Crusher shafts, drive gears, support blocks, and custom heavy-duty parts

- Rail & Transportation: Axle bars, couplings, and critical suspension components

- Defense & Military: Tank components, armor plate, and missile parts

- Custom Tooling & Equipment: Large dies, molds, and specialty forging tools

Curious about whether open-die forging is suitable for your industry or application? Ask yourself: Does my part require exceptional strength, reliability, or customization? Do I need a supplier that can handle large dimensions or challenging alloys? If the answer is yes, open-die forging may be the ideal solution.

Comparing Open Die Forging vs. Closed Die Forging

Buyers often seek clarification on the differences between open-die forging and closed-die forging. Here’s a brief comparison:

- Open Die Forging: Best for large or simple shapes, custom or low-volume production, and superior mechanical properties due to continuous grain flow.

- Closed Die Forging: Ideal for high-volume production of complex, detailed parts with tight tolerances and repeatability. Requires dedicated tooling and dies.

Still not sure which process is right for your project? Explore: What are the cost implications of each method? How do lead times compare? Will the finished part require additional machining or heat treatment?

How to Select an Open Die Forging Company

Choosing the right open die forging company is essential to ensure quality, reliability, and value. When searching for a supplier, consider the following decision factors:

- Experience & Capabilities: Does the company have a proven track record with similar projects, materials, and part sizes? Review their certifications and industry expertise.

- Equipment & Capacity: Can they handle the size, weight, and complexity of your requirements? Are they equipped for high-alloy or specialty metal forging?

- Quality Assurance: What quality control processes, testing, and documentation do they offer? Are they compliant with industry standards such as ISO 9001 or AS9100?

- Engineering Support: Do they provide in-house design assistance, simulation, or metallurgy expertise to optimize your part?

- Lead Times & Scalability: Are they able to meet your deadlines and adapt to changes in production volume?

- Cost Effectiveness: How do their pricing models and material sourcing align with your project budget?

To ensure the best outcome when purchasing from an open die forging supplier, it’s highly recommended to compare at least four companies using our curated list of open die forging companies. Review each company profile for details on expertise, equipment, and certifications. Utilize our patented website previewer to assess their capabilities, and quickly request quotes or additional information using our streamlined RFQ form.

Frequently Asked Questions About Open Die Forging

- What sizes and weights can be achieved with open-die forging? Open-die forging is capable of producing parts ranging from a few pounds to over 150 tons, with lengths exceeding 80 feet in some cases.

- What is the typical lead time for custom open-die forged parts? Lead times vary by part complexity, material, and supplier capacity, but most projects can be delivered in 4–12 weeks.

- Can open-die forging be used with specialty or high-temperature alloys? Yes, reputable open-die forging companies have experience with titanium, nickel superalloys, stainless steel, and other exotic metals.

- Is post-forging machining or heat treatment required? Many forged parts require finish machining and heat treatment (such as annealing, quenching, or tempering) to achieve final dimensions and properties.

- What industries benefit most from open-die forging? Aerospace, oil and gas, power generation, mining, transportation, and marine industries are major users of open-die forged components.

Request a Quote or Consultation for Open Die Forging

Ready to start your project or need expert guidance? Contact leading open die forging companies through our platform to discuss your requirements, request a quote, or learn more about custom material options and value-added services.

Looking for more resources? Browse our metal forging resource center for in-depth articles, comparison guides, and industry insights.

Conclusion: Why Open Die Forging Is a Top Choice for High-Performance Metal Components

Open-die forging remains the gold standard for producing large, durable, and custom metal parts that demand the highest levels of strength, reliability, and metallurgical integrity. By understanding the open-die forging process, applications, material options, and supplier selection criteria, buyers can make informed decisions and secure the best value for their projects. Whether you require a single prototype or a series of industrial components, open-die forging delivers unmatched performance for the most demanding applications.

Ready to take the next step? Compare open die forging companies now to find the ideal partner for your needs.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services